Screen Printing

Ellen’s Silkscreening is a medium sized apparel printing and embroidery company based in South Pasadena, California. We regularly handle printed and embroidered orders of between 24 and 5,000 units in-house on a 7-10 working day turnaround. Our knowledgeable sales team also sources out printed promotional product orders to a large network of vendors on a daily basis.

silkscreening, silk screen, screen printing, embroidery, embroider, applique, promotional products, drinkware, notebooks, flash drives, pens, pencils, banners, bottle openers, lanyards, balloons, keychain fobs, flash lights, sunglasses, T-Shirts, Sweatshirts, Polos, Knits, Layering, Fleece, Woven Shirts, Outerwear, Pants, Shorts, Infants and Toddlers, Headwear, Bags, Accesories,

22868

wp-singular,page-template-default,page,page-id-22868,wp-theme-stockholm,qode-social-login-1.1.3,qode-restaurant-1.1.1,stockholm-core-2.3,select-theme-ver-9.4,ajax_fade,page_not_loaded,menu-animation-underline,,qode_menu_,wpb-js-composer js-comp-ver-6.6.0,vc_responsive,elementor-default,elementor-kit-25840

40 years of Silkscreening Experience

Ellen’s Silkscreening specializes in quality custom screen printing. We can silkscreen on just about any kind of apparel you can imagine as well as on tote bags.

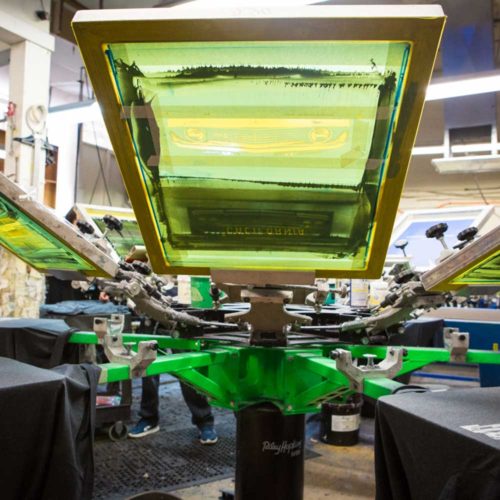

Screen printing is a printing technique that pushes ink through a porous mesh screen stretched across a frame.

The image that is printed is created by a stencil image that is fixed on the screen. The stencil image is created by applying a photo sensitive emulsion to a screen, placing a film positive on the emulsion, and exposing the emulsion to bright light.

The screen is then pressure washed and the unexposed emulsion falls away, creating a negative image on the screen. The screen is then dried and carefully registered on a printing press.

Heavy duty rubber squeegees are used to push ink through the negative areas of the screen onto a substrate (that might be a t-shirt, a sweatshirt, or a tote) to create the final imprint image. The item being printed then passes on a conveyor belt through an oven that cures the imprint ink.

Because of the considerable prep work required for screen printing, our order minimum is 48 units.

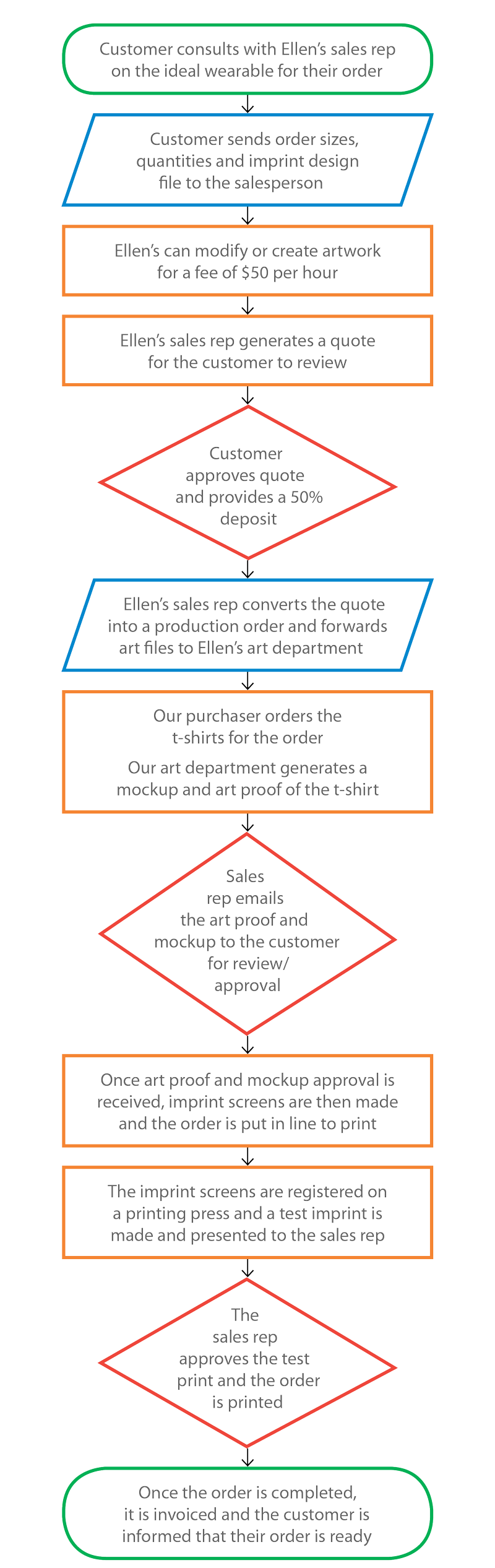

Screen Printing Order Step by Step

What Will Your Experience Be?

The turnaround was on schedule, easy to get a hold of when you have a question, knowledgeable staff, good quality work.

- Isaac A.5 Stars

I highly recommend Ellen's for all your silkscreening needs.

- Mark G.5 Stars

Ann Marie [my sales rep] was incredibly helpful and patient in answering all my questions. I even got a phone call from the owner after picking up the shirts thanking me for my business!

- Mark G.5 Stars

…the folks at Ellen's came to the rescue and helped me get the most attractive shirts at the best value.

- Mark G.5 Stars

Quality and quick turn around on orders! Will certainly use their services again.

- Luisa J.5 Stars

Prompt and friendly service! Our students were so happy with their t-shirts and hoodies.

- Luisa J.5 Stars

I look forward to working with Jan [my sales rep] and Ellen's Silkscreening in the very near future. Five stars!

- Regina N.5 stars

In less than one hour, I was sent two PDFs with quotes for both of them [t-shirts]. Incredible service.

- Regina N.5 stars

Following a big smile and firm handshake, Jan [my sales rep] walked me through Ellen's process of silkscreened t shirts (I'm new to all of this!)… I probably asked Jan about a million questions, and he had a quick and informative answer to every single one.

- Regina N.5 stars

This was a great year and we so appreciate the expertise, service and beautiful quality work we always receive from you and Ellen's entire staff.

- Terri ColpoPasadena Heritage Volunteer

...Ellen's offered the best price for what my boss had me looking for so we decided to give them a try. Definitely worth it will be using them again for future orders.

- Joseph L.5 Stars

Friendly service, fast production, competitive prices; more importantly, quality work. That's what you will get from this company.

- Joseph L.5 Stars

I just want to let you and Ellen know that this year’s shirt for the Celebration on the Colorado Street Bridge was a big success and a big seller!

- Terri ColpoPasadena Heritage Volunteer

I was thoroughly satisfied with Ellen's help and support to get these t-shirts made on time and exactly as we had discussed. I highly recommend Ellen's Silkscreening.

- Sean W.5 Stars

I was met with warm interest in my project, feasible options in how to get it done and a great timetable as well as reassurance on how this could be done, and done well.

- Sean W.5 Stars

Their work was of the best quality, priced fairly and was completed on time. To top it all off, Ellen followed up by leaving the nicest voicemail for me. I will definitely be back.

- Ry K.5 Stars

…the experience really couldn't have been any better. Ann Marie [our sales rep] was an absolute joy to work with; she was always friendly, responsive and creative.

- Ry K.5 Stars

For shirts, hats, other promo items for school, church, bar or bat mitzvah – they are great!

- Jennifer G.5 Stars

I was so happy in the end that we did not end up ordering on line from some company in another part of the country and I was happy were able to support a local family business in our neighborhood.

- Jennifer G.5 Stars

The price was awesome, and the people who work at Ellen's could not be any nicer to deal with.

- Jennifer G.5 Stars

They worked with us on cost and our budget (LAUSD is so tight!!). The shirts came out PERFECT.

- Jennifer G.5 Stars

They were able to get us great 100% cotton tshirts - in all the sizes we need - with gorgeous screening in just one day.

- Jennifer G.5 Stars

I recommend Ellen's to everyone! Howard [manager of Ellen's] and his team are the greatest!!!

- Jennifer G.5 Stars

The staff is super helpful and accommodating. Highly recommend, all the way around!

- Bonny A.5 Stars

I am so happy with the items I have received from Ellen's Silkscreening…They all have been great quality items and the printing has been perfect. I cannot be more thrilled!

- Bonny A.5 Stars

They are excellent at what they do and the staff is great! They are courteous, knowledgeable and very accommodating.

- Robyn M.5 Stars

I own a small business and would highly recommend them to anyone.

- Robyn M.5 Stars

We received a lot of compliments on this particular event; a huge part was due to how easy Ellen's made it! I will continue to use them for all my promotional product and t-shirt needs!

- Leilani S.5 Stars

They were able to print beautiful glossy folders for us at literally almost half the cost of what I had been looking at elsewhere online, and the design was consistent with the t-shirts.

- Leilani S.5 Stars

Not only did they work closely with me on each step in the design process, they recommended the best type of printing (heat transfer) for this particularly detailed design - it came out fabulous.

- Leilani S.5 Stars

Even with very short notice, they have given excellent attention to detail in printing shirts that we needed sometimes less than a week out.

- Leilani S.5 Stars

The quality and pricing were great! Support local, go Ellen's!

- Melea F.5 Stars

The order was completed ahead of time and everything looks fabulous. Thanks for the great job and I'll definitely come back for future orders.

- E. Todd S.5 Stars

It was great to be able to feel and try on the shirts prior to choosing which ones would be best for our order.

- E. Todd S.5 Stars

I had a great experience with the employees who were very helpful in providing multiple choices of shirts and colors that might work for the screen prints I was looking to do.

- E. Todd S.5 Stars

… I like the human advertising season after season on well worn lovable products from Ellen's.

- Jennie C.5 Stars

…I like supporting local businesses that give back to the community in big ways.

- Jennie C.5 Stars

Last year I got all my staff rain jackets for Christmas, and they LOVED them. And they were flattering and stylish too.

- Jennie C.5 Stars

The staff has always guided me through the process, they keep a file of all my screens and have great suggestions on products.

- Jennie C.5 Stars

It's a great place to do business.

- Jennie C.5 Stars

I was completely satisfied with their service, expertise, and print quality.

- Matthew C.5 Stars

The finished product exceeded my expectations. Not only that, they finished a huge order in just a few days notice.

- Matthew C.5 Stars

Howard [manager of Ellen's] took care of me the whole way, going over every detail until I received my shirts. He was great! Very professional and thorough.

- Matthew C.5 Stars

She [Ellen] and her staff have always been knowledgeable and helpful with all of our orders. Ellen is a fine businesswoman and a pillar of the community.

- Nancy L.5 Stars

They [appliqué garments] were such a hit that we will continue to order more for our VIP customers! This could not have worked out better!

- John N.5 Stars

Worked with us on the pricing so we were also able to have our current logo screened onto the garments as well.

- John N.5 Stars

Very easy to reach with questions and they had suggestions that worked out great.

- John N.5 Stars

I will continue to work with Ellen's in the future. Definitely recommend.

- Isaac A.5 Stars

The professional step by step process made it easy on me since this was my first time getting screen print services.

- Isaac A.5 Stars

It's a very nice and clean shop, so I thought it would be expensive. Nope. Not at all. In fact, Ellen's rates were much lower than some rinky-dink shops that I had been quoted by.

- Isaac A.5 Stars